STM (Surface Transition Machine) is a surface transition device that enables stable bonding of zirconia restorations.

By applying thermal energy, it induces localized etching and sintering on the zirconia surface,

creating a hydrophilic surface and forming macro- and micro-undercuts that enhance bonding strength.

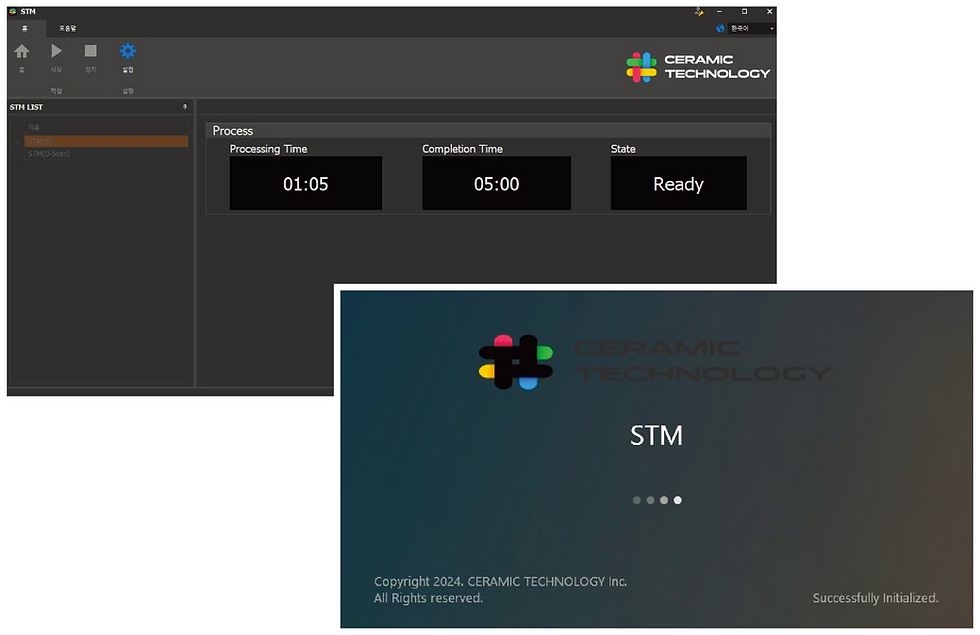

STM Software is a dedicated program designed exclusively for the STM device.

By selecting the appropriate settings according to the characteristics of the restoration, the operation can be initiated with just a simple click.

In addition to start and stop functions, it intuitively displays processing time and completion status, allowing for easy and quick use without the need for additional training.

O/S: Windows 7, 10, 11 (64-bit)

Specifications

• Model : STM-Z

• Method : STM (Surface Transition Mechanism)

• Applicable Material : Zirconia

• Cavity : 1 ea

• Size : 400(W) × 800(H) × 650(D) mm

• Weight : 50 kg

• Power : 100–240V (AC), 50–60 Hz

Water droplet on untreated zirconia surface

Water droplet on STM-treated zirconia surface

-

The smaller the water droplet contact angle on the STM-treated zirconia surface, the higher the surface hydrophilicity becomes.

-

Increased hydrophilicity of the zirconia surface is a critical factor in achieving strong zirconia bonding.

Acid etching & Silane

+ Adhesive Resin

Surface treatment with STM only

— no additional process required

Surface treatment + Adhesive Resin

-

STM-treated zirconia demonstrates over 40% stronger bonding strength than lithium disilicate.

-

Without any chemical treatment such as acid or silane, STM-treated zirconia alone achieves exceptional bonding performance.

STM (Surface Transition Machine) is a surface transition device that enables stable bonding of zirconia restorations.

By applying thermal energy, it induces localized etching and sintering on the zirconia surface,

creating a hydrophilic surface and forming macro- and micro-undercuts that enhance bonding strength.

STM Software is a dedicated program designed exclusively for the STM device.

By selecting the appropriate parameters based on the characteristics of the restoration,

the system operates with just a simple click.

In addition to start and stop functions, it provides intuitive displays of processing time and completion status,

allowing for easy and efficient operation without the need for additional training.

O/S: Windows 7, 10, 11 (64-bit)

Specifications

-

O/S : Windows 7, 10, 11 (64bit)

-

Model : STM-Z

-

Method : STM (Surface Transition Mechanism)

-

Applicable Material : Zirconia

-

Cavitv: 1 ea

-

Applicable Material : Zirconia

-

Cavity: 1 ea

-

Size : 400(W) X 800(H) X 650(D) mm

-

Weight: 50 kg

-

Power: 100-240V (AC), 50-60 Hz

Micro Retention

Macro Retention

Adhesive Surface

Macro Retention

Cross-section

Water droplet on untreated zirconia surface

Water droplet on STM-treated zirconia surface

-

The smaller the water droplet contact angle on the STM-treated zirconia surface,

the higher the hydrophilicity of the zirconia surface becomes.

-

Increased hydrophilicity of the zirconia surface is a crucial factor for achieving strong zirconia bonding.

Acid etching & Silane

+ Adhesive Resin

Surface treatment with STM only

— no additional process required

Surface treatment + Adhesive Resin

-

STM-treated zirconia demonstrates over 40% stronger bonding strength than lithium disilicate.

-

Without any chemical treatment such as acid or silane, STM-treated zirconia alone achieves exceptional bonding performance.